Suggested retail price

Technology

Aluminium heat exchanger with hydrophilic coating

Improved wettability of the heat exchanger aluminum plates which have a special coating with a hydrophilic layer, ensuring rapid removal of condensate from the indoor unit that does not allow to quickly form of mold and bacteria, providing a more efficient operation of the air conditioner.

Central Controller

- The central controller is used for centralized management of indoor units (up to 64 indoor units can be connected via an adapter card).

- The indoor units can be divided into 20 zones, each zone can contain no more than 64 indoor units. All indoor units in one zone can only be set to the same mode. (By default, "the zone is not assigned to indoor units").

- Users can select the desired mode and temperature with a weekly schedule.

360°Air Flow Panel

With the 360°air flow panel, the air can be distributed to every corner of the room.

Motor DC inverter indoor unit

The indoor unit is used to rotate the impeller DC - motor. This can significantly reduce noise and power consumption. And also get 12 positions change the speed of the impeller.

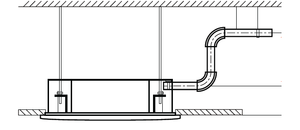

Redirecting the flow of air to neighboring rooms using air ducts

With the help of air ducts, it is possible to organize the redirection of part of the treated air flow to neighboring rooms.

The mixing of fresh air

Organization of fresh air - by a separate duct (in a split system with such a function, the duct is usually a small diameter and is laid along the highway) ...

Wired remote control for indoor unit

The internal block is completed / can be completed (option) with the wire control panel.

General functional features:

- Connection to indoor units using stranded wire.

- The job modes.3. Set the fan speed.

- Display information about operating modes on the LCD.

- Setting the time of automatic on / off using a timer.

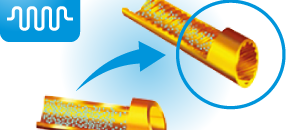

Multi-Bend Heat Exchanger

Increased heat. This unit uses the heat exchangers with tubes of a special design, the inner surface of which has trapezoidal notches "Innergrove cooper", which provides maximum heat transfer surface area increased. Due to this heat increases by 28%, reduced power consumption, and hence increases the efficiency of the system.

Description

- CE-MBQ-03C4 panel,

- DC fan motor,

- Built-in water pump,

- The possibility of organizing an inflow of fresh air,

- Remote control is an option.

Specifications

| Model | MI2-22Q4CDHN1 | MI2-28Q4CDHN1 | MI2-36Q4CDHN1 | MI2-45Q4CDHN1 | ||

| Power supply | 1-phase, 220-240V, 50/60Hz | |||||

| Cooling1 | Capacity | kW | 2.2 | 2.8 | 3.6 | 4.5 |

| kBtu/h | 7.5 | 9.6 | 12.3 | 15.4 | ||

| Power input | W | 35 | 35 | 40 | 50 | |

| Heating2 | Capacity | kW | 2.4 | 3.2 | 4.0 | 5.0 |

| kBtu/h | 8.2 | 10.9 | 13.6 | 17.1 | ||

| Power input | W | 35 | 35 | 40 | 50 | |

| Fan motor type | DC | |||||

| Indoor coil | Number of rows | 1 | 2 | |||

| Tube pitch × row pitch | mm | 21×13.37 | 21×13.37 | |||

| Fin spacing | mm | 1.3 | 1.3 | |||

| Fin type | Hydrophilic aluminum | |||||

| Tube OD and type | mm | Ф7 Inner-groove | ||||

| Dimensions (L×H×W) | mm | 1310×210×13.37 | 1310×210×26.74 | |||

| Number of circuits | 2 | 4 | ||||

| Air flow rate3 | m3/h | 414/380/345/313/288/268/238 | 521/485/450/409/380/350/314 | |||

| Sound pressure level4 | dB(A) | 35/34/33/29/26/23/22 | 41/38/35/32/30/29/28 | |||

| Main body | Net dimensions5 (W×H×D) |

mm | 630×260×570 | |||

| Packed dimensions (W×H×D) |

mm | 700×345×660 | ||||

| Net/Gross weight | kg | 18/23.8 | 19.2/25.0 | |||

| Panel | Model | CE-MBQ-03C4 | ||||

| Net dimensions (W×H×D) | mm | 647×50×647 | ||||

| Packed dimensions (W×H×D) |

mm | 715×123×715 | ||||

| Net/Gross weight | kg | 2.5/4.5 | ||||

| Refrigerant type | R410A | |||||

| Design pressure (H/L) | MPa | 4.4/2.6 | ||||

| Pipe connections | Liquid/Gas pipe | mm | Ф6.35/Ф12.7 | |||

| Drain pipe | mm | OD Ф25 | ||||

| Notes: | ||||||

| 1. Indoor temperature 27°C DB, 19°C WB; outdoor temperature 35°C DB; equivalent refrigerant piping length 7.5m with zero level difference. | ||||||

| 2. Indoor temperature 20°C DB; outdoor temperature 7°C DB, 6°C WB; equivalent refrigerant piping length 7.5m with zero level difference. | ||||||

| 3. Air flow rate are from the highest speed to the lowest speed, total 7 rates for each model. | ||||||

| 4. Sound pressure level is from highest level to lowest level, total 7 levels for each model. Sound pressure level is measured 1.4m below the unit in a semi-anechoic chamber. | ||||||

| 5. Unit body dimensions given are the largest external dimensions of the unit, including hanger attachments. | ||||||