Operating ambient temperatures

Suggested retail price

Technology

Blue Fin

Blue fin heat exchanger cover - Protection against corrosion. Special anti-corrosion coating of the heat exchanger, protection from atmospheric phenomena and effects of aggressive environment. May differ in color (have blue, green, gold or no color at all (clear varnish)

Sine-Wave Inverter

Technology 180° -gradusnogo wave inverter conversion - control voltage without the "pulse" effects (jagged sinusoid).

Compared with the current standard of 120° rectangular wave has the following advantages:

- Ability to work with a wider range of supply voltage and frequency.

- Most of the energy efficiency and energy conservation.

- More soft start, lower noise and vibration.

- more control.

Refrigerant Leakage Detect

Its a electronical function of Main PCB and self-diagnostic system into AC.

When pipe-temperature sensor at inlet line of evaporator will indicate highest temperature, system will indicate "EC" code in a display of indoor units, its mean "ask for service centre for visit maintance team with leakage detectors and tools"

Compresor DC inverter

Compressor with inverter DC can increase the efficiency of the air conditioner, thus reducing power consumption saves your costs. This system is much more economical and safer than air conditioners with a constant output of the compressor.

Ozone-friendly freon R32

The new refrigerant R32 (difluoromethane) has significant advantages. First of all, it concerns the potential of global warming (GWP). If we compare the highly popular R410A refrigerant with R32, the latter differs by more than 65% of the GWP reduced. It follows that the environment is less affected by the new refrigerant. Also, R32 is characterized by reduced viscosity and density. Due to the lower density, the freon consumption is reduced, taking into account the same power figures. The density of difluoromethane is almost 30% less than that of R410A.

Multi-Bend Heat Exchanger

Increased heat. This unit uses the heat exchangers with tubes of a special design, the inner surface of which has trapezoidal notches "Innergrove cooper", which provides maximum heat transfer surface area increased. Due to this heat increases by 28%, reduced power consumption, and hence increases the efficiency of the system.

Description

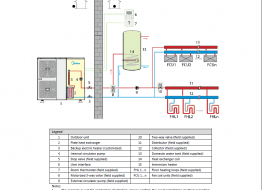

The principle of operation of a conventional air conditioner is based on the fact that, in cooling mode, the refrigerant, boiling in the heat exchanger (evaporator) of the indoor unit of the air conditioner, absorbs the heat of the room air and transfers it with the help of a compressor to the heat exchanger (condenser) of the external unit, where the condensation of the refrigerant occurs heat, which is transferred to the environment. The principle of the work of the heat pump is "reverse" - it is based on the transfer of thermal energy from the atmosphere (ambient air) - to the consumer, with the help of the cycle of steam-compression machine operation, which, in turn, heats up, a refrigerant which, through the heat exchanger, "freon-water" provides heating the water in a boiler indirect heating. The storage tank is needed in the system to equalize the heat flow between the source and consumers, as well as in it, it is possible to arrange additional heating of water (heat carrier) with the help of an electric heater and / or an additional circuit from the solar collector, solid fuel boiler, etc. Further, as in the traditional heating system, hot water through the pumping group is supplied to the distribution group, from which comes the closing devices (fan coils), radiators or loops of warm floor and other types of consumers for cooling or heating room air.

Use in this equipment of the modern ozone-depleted freon R32 allows you to improve the performance of the system as a whole and reduce its electropotential.

With the cost of just 1 kW of electrical energy for the operation of the compressor and veneylators of this system, it is possible to obtain the heat output of the capacitor from 4.65 to 6.65 kW, depending on the temperature on the street, the frequency of defrost cycles and heat losses in the room.

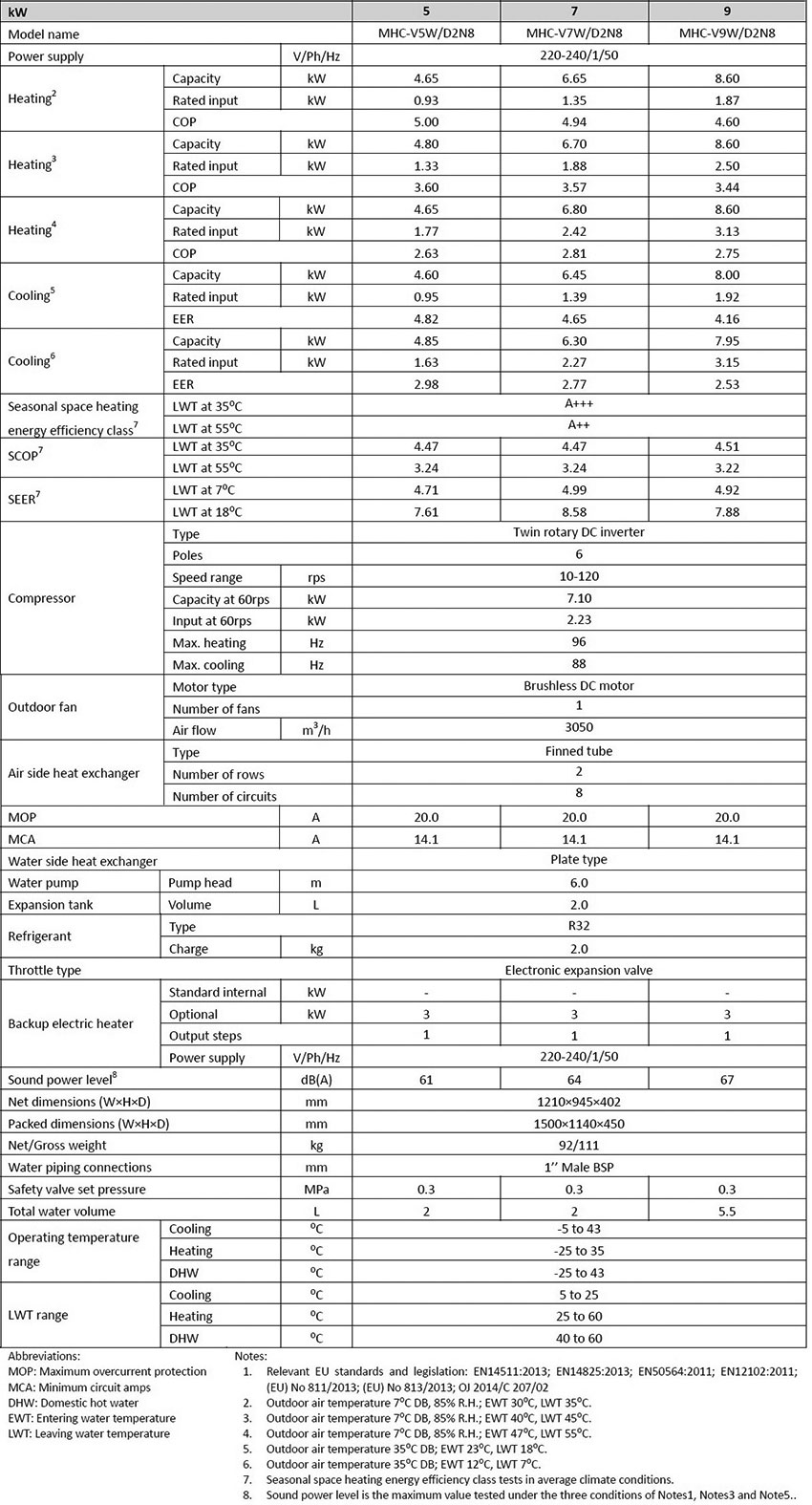

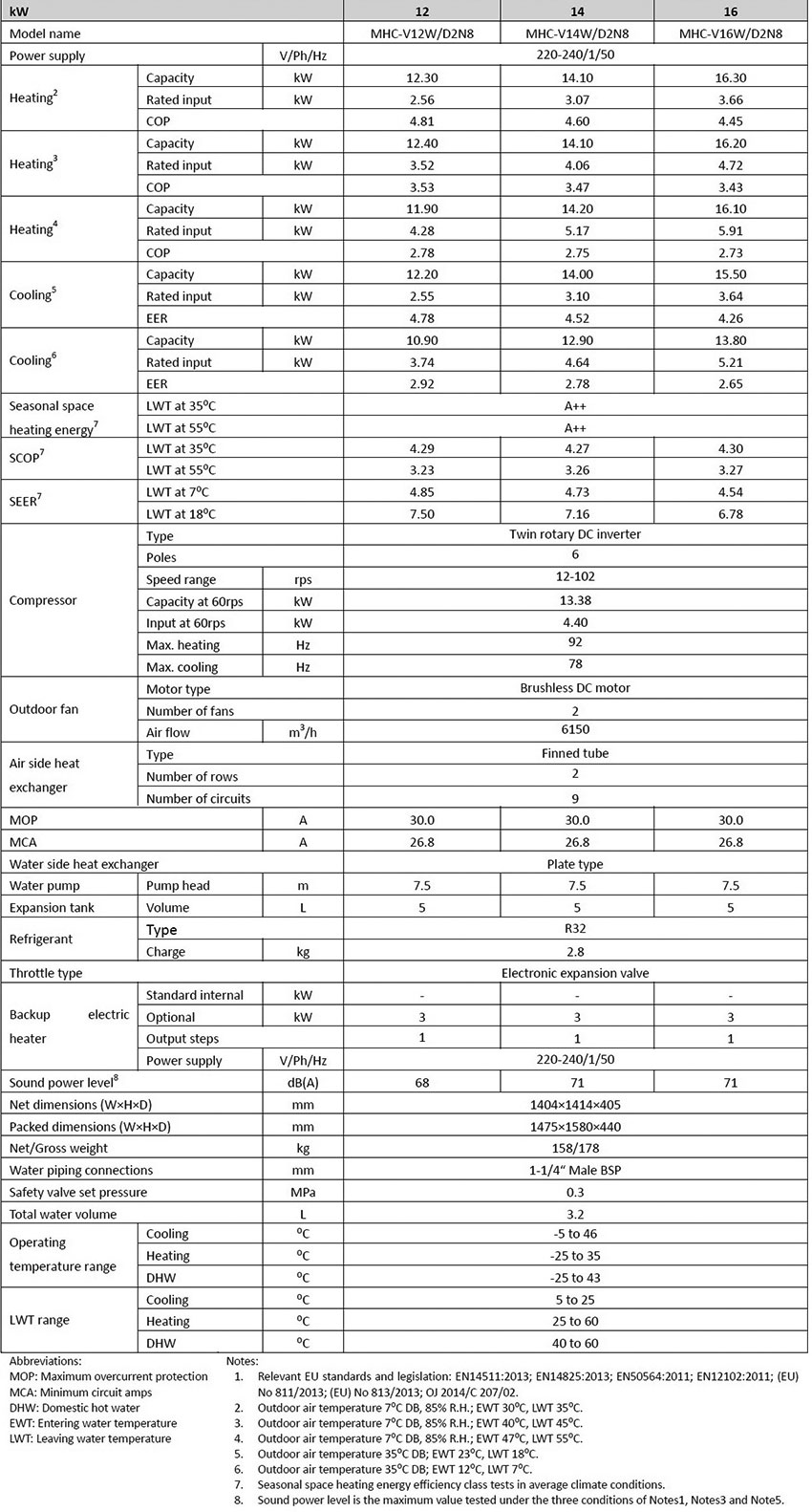

Specifications

| Model name | MHC-30W/D2RN8 | ||

| Power supply | V/Ph/Hz | 380-415/3/50 | |

| Heating1 | Capacity | W | 30100 |

| Rated input | W | 8027 | |

| COP | 3.75 | ||

| Heating2 | Capacity | W | 30000 |

| Rated input | W | 10345 | |

| COP | 2.90 | ||

| Heating3 | Capacity | W | 30000 |

| Rated input | W | 13043 | |

| COP | 2.30 | ||

| Cooling4 | Capacity | W | 30000 |

| Rated input | W | 12766 | |

| EER | 2.35 | ||

| Cooling5 | Capacity | W | 31000 |

| Rated input | W | 7750 | |

| EER | 4.00 | ||

| Seasonal space heating energy efficiency class6 | Water outlet at 35oC | class | A++ |

| Water outlet at 55oC | class | A+ | |

| Refrigerant | Type | R32 | |

| Charged volume | kg | 5.0 | |

| Sound power level | dB | 77 | |

| Unit dimension (W×H×D) | mm | 1129x1558x528 | |

| Packing dimension (W×H×D) | mm | 1220x1725x565 | |

| Net/Gross weight | kg | 177/206 | |

| Water piping connections Dia. | inch | 1-1/4“ BSP | |

| Ambient temperature range | Cooling | oC | -5-46 |

| Heating | oC | -25-35 | |

| DHW | oC | -25-43 | |

| Water outlet temperature range | Cooling | oC | 5-25 |

| Heating | oC | 25-60 | |

| DHW | oC | 40-60 | |

| Notes: | |||

| 1.Evaporator air in 7oC, 85% R.H., Condenser water in/out 30/35oC | |||

| 2.Evaporator air in 7oC, 85% R.H., Condenser water in/out 40/45oC | |||

| 3.Evaporator air in 7oC, 85% R.H., Condenser water in/out 47/55oC | |||

| 4.Condenser air in 35oC. Evaporator water in/out 12/7oC | |||

| 5.Condenser air in 35oC. Evaporator water in/out 23/18oC | |||

| 6. Seasonal space heating energy efficiency class testes in average climate general | |||

| 7. The above data test reference standard EN14511; EN14825; EN50564; EN12102; (EU) No:811:2013; (EU)No:813:2013; OJ 2014/C 207/02:2014 | |||