Suggested retail price

Technology

Blue Fin

Blue fin heat exchanger cover - Protection against corrosion. Special anti-corrosion coating of the heat exchanger, protection from atmospheric phenomena and effects of aggressive environment. May differ in color (have blue, green, gold or no color at all (clear varnish)

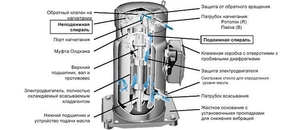

Compresor DC inverter

Compressor with inverter DC can increase the efficiency of the air conditioner, thus reducing power consumption saves your costs. This system is much more economical and safer than air conditioners with a constant output of the compressor.

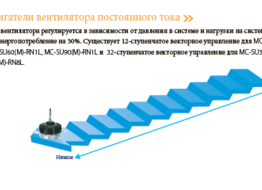

DC inverter motor Outdoor Unit

In outdoor units, a DC motor is used to rotate the fan. This allows you to significantly reduce noise and power consumption. And also get several positions of the fan speed, depending on the needs of the system.

Wired remote control the chiller

Supplied with the chiller;

Provides restart with pre-set parameters, with the loss of elektenergii;

It has an informative liquid crystal display, which displays the operating modes and fault codes when they occur.

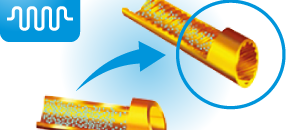

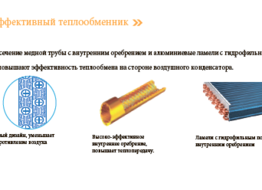

Multi-Bend Heat Exchanger

Increased heat. This unit uses the heat exchangers with tubes of a special design, the inner surface of which has trapezoidal notches "Innergrove cooper", which provides maximum heat transfer surface area increased. Due to this heat increases by 28%, reduced power consumption, and hence increases the efficiency of the system.

Sine-Wave Inverter

Technology 180° -gradusnogo wave inverter conversion - control voltage without the "pulse" effects (jagged sinusoid).

Compared with the current standard of 120° rectangular wave has the following advantages:

- Ability to work with a wider range of supply voltage and frequency.

- Most of the energy efficiency and energy conservation.

- More soft start, lower noise and vibration.

- more control.

Description

The range of modular inverter chillers includes units for - 30, 60, 90 kW. Optionally, when ordering from the factory, you can install: an integrated pump, an integrated expansion tank of 100 liters. It is recommended that you use prepared water to refuel the system, as heat exchangers in this series are plate heat exchangers.

Also in the chillers, a control board is installed with a connection to the KJRM-120N / BMWКO-E wired control panel, which allows changing the temperature settings of the coolant in the range from 0 ° C to 17 ° C for cooling and from 25 ° C to 50 ° C for heating mode

Specifications